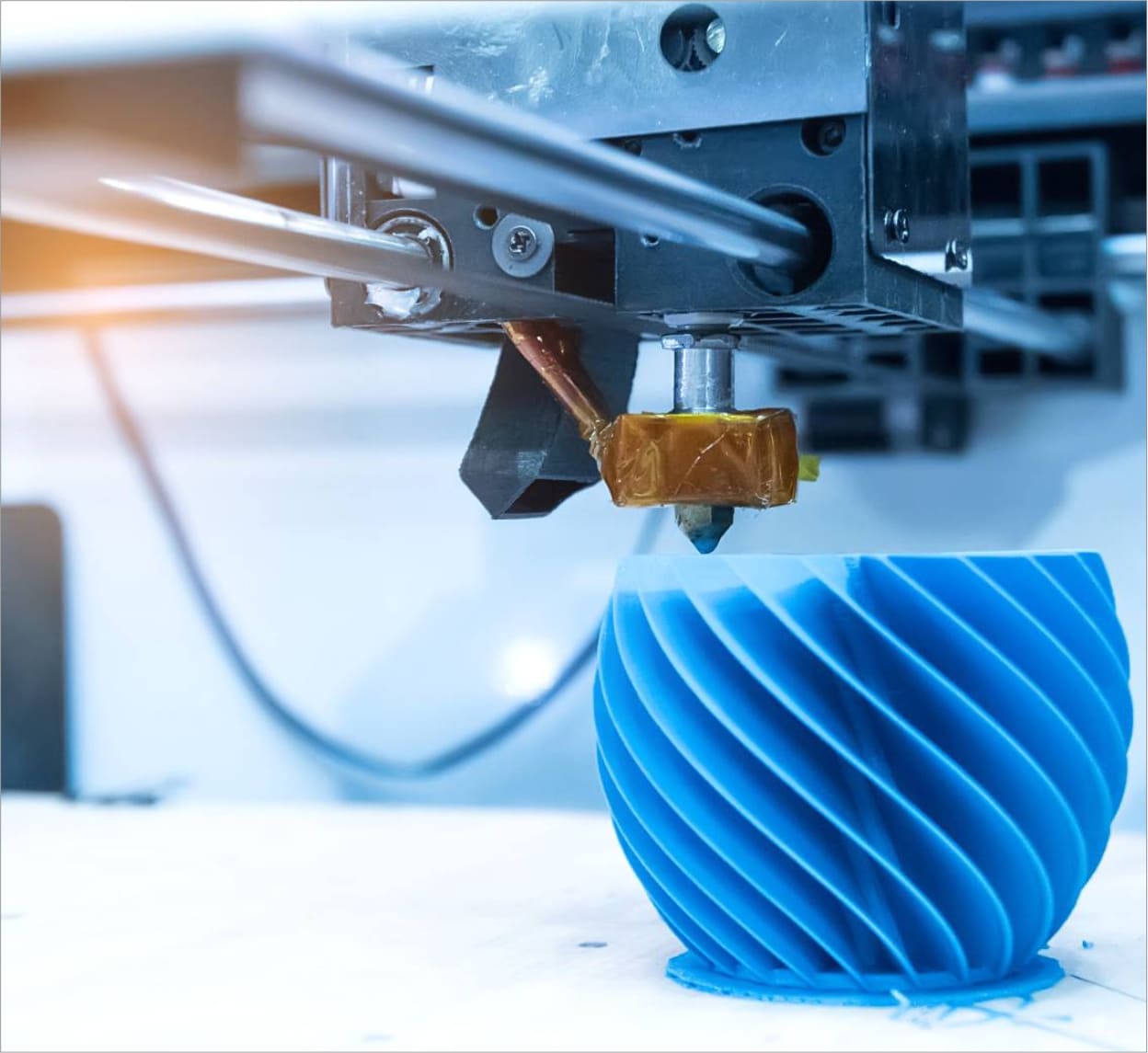

One of the most important changes in manufacturing today is the shift toward digital transformation of all kinds. To put it simply, digital transformation is the process of using digital technology to change the way a company works, its products, and its services into something new and better. Industrial companies can become more productive, save money, and gain a competitive edge through digital transformation.

Need for Digital Transformation

In the next few years, digital technology will change the way companies make, deliver, and sell manufactured goods in a way that will be very different from how it is now. The business models that organizations use to run will also change massively.

Companies are becoming more and more dependent on digital transformation to help them reach their goals, run their businesses more efficiently, and grow. Digital transformation is now an urgent need in the manufacturing sector. Transforming a single area isn’t enough; it’s a consistent cycle that keeps a business moving forward and makes it an important thing to take care of today. If a company stops the cycle of digital transformation, it will fall behind compared to its competitors in the market and gradually lose its current market share. Using a digital transformation strategy in manufacturing has many benefits, such as increasing production and making more money.

Digital transformation means that many different systems and technologies must be coordinated and linked together for manufacturing processes to become more efficient and successful. In the modern manufacturing industry, there has been a big change from the old way of making things to more modern digital architecture. By using digital transformation strategies to streamline and automate their business operations, manufacturers can cut costs and generate more revenue.

Digital Transformation Trends in the Manufacturing Industry

In order to stay competitive, the manufacturing industry is being pushed to become more digital. Technology can help manufacturers deal with problems like rising costs, a drop in demand, or more competition by making them more efficient and better at what they do.

The industrial sector as a whole is under pressure to adapt digitally to stay competitive. By using new technologies, manufacturers can improve their output, quality, and ability to change.

How has Digital Transformation impacted the Manufacturing sector?

Nevertheless, the transition to digital production in the manufacturing business comes with its own unique set of problems as well. It is possible that the frequency of cyberattacks against manufacturing facilities may increase as these facilities become more reliant on digital technologies. Because digital transformation programmes can be difficult and expensive to implement, it is possible that some companies will not be able to make the most of their potential because they will lack the essential skills and resources.

Many businesses still struggle with enabling digital transformation in order to generate the plethora of benefits that come with it. The team of experts at Eteva Tech help make your business future-ready by streamlining internal processes as well as production operations right from onboarding new technologies to optimising your business for better ROI. Reach out to us or check our website to know more about our services.

0 Comments